Introduction

The battle against clutter in workshops and garages is ongoing for many homeowners and DIY enthusiasts. Tools scattered across workbenches, equipment piled in corners, and the frustration of not finding what you need when you need it—these are common challenges that can turn productive project time into a treasure hunt for that one specific wrench or drill bit.

Wall organization systems offer an elegant solution to this chaos by utilizing vertical space effectively. Three popular options dominate the market: pegboard, slatwall, and French cleat systems. Each offers a unique approach to organizing your tools and equipment, with distinct advantages and disadvantages that make them suitable for different users and situations.

In this comprehensive guide, we'll explore these three organization systems in detail, comparing their features, costs, installation requirements, and best use cases. By the end, you'll have a clear understanding of which system might be the perfect fit for your specific needs, whether you're setting up a professional workshop, organizing a garage, or creating a craft space.

Before diving into the specifics of each system, it's worth taking a moment to consider your own organizational needs and priorities. The "best" system isn't universal—it depends entirely on your unique situation, tools, budget, and aesthetic preferences. Let's begin by examining what factors you should consider when choosing a wall organization system.

Understanding Your Organization Needs

Before committing to any organization system, it's essential to assess your specific requirements. This evaluation will help guide your decision-making process and ensure you select a system that truly meets your needs rather than creating new frustrations.

Assessing Your Space and Tools

Start by taking inventory of what you need to organize. Different tools and equipment have different storage requirements:

- Hand tools like hammers, screwdrivers, and wrenches can be hung on most systems, but their quantity and weight should be considered.

- Power tools often require specialized holders or sufficient weight capacity.

- Bulky equipment such as ladders, bicycles, or lawn care tools need robust mounting solutions.

- Small items like screws, nails, and bits benefit from container storage that can be mounted on your wall system.

The dimensions of your available wall space also matter significantly. Measure the height, width, and any obstructions like windows, electrical outlets, or light switches that might affect installation.

Considering Your Budget

Organization systems vary widely in cost, both for initial setup and long-term expansion:

- Pegboard is typically the most budget-friendly option, especially hardboard varieties.

- Slatwall represents a mid-to-high-range investment, with costs varying based on material quality.

- French cleat systems can be economical if you build them yourself, but purchasing pre-made components or using high-quality materials can increase costs.

Remember to factor in not just the wall panels or mounting strips, but also the accessories, hooks, holders, and brackets you'll need to complete your system.

Evaluating Your DIY Skills

Your comfort level with tools and installation projects should influence your choice:

- Pegboard installation is relatively straightforward, requiring basic tools and skills.

- Slatwall often demands more precise installation and may require specialized panels and techniques.

- French cleat systems can be simple or complex depending on your approach, but building custom holders requires basic woodworking skills.

If you're not confident in your installation abilities, consider whether professional installation is available and how that affects your budget.

Thinking About Aesthetics and Long-Term Plans

The visual impact of your organization system matters, especially in spaces that are visible to guests or serve multiple purposes:

- Pegboard has a utilitarian, classic workshop look. Coupled with modern design of Wallwerx pegboard accessories, what was old is new again.

- Slatwall offers a more modern, clean appearance and comes in various colors and finishes.

- French cleat systems can have a minimalist, custom-built aesthetic that many woodworkers appreciate.

Also consider how your needs might evolve over time. Will you be acquiring more tools? Might your workshop focus change? The adaptability and expandability of your chosen system could become increasingly important as your collection grows or your interests shift.

Pegboard - The Classic Solution

When most people think of workshop organization, pegboard is often the first system that comes to mind. This classic solution has been a staple in garages and workshops for decades, offering a simple yet effective way to keep tools visible and accessible.

What Is Pegboard?

Pegboard (also called perforated hardboard) is a panel material with evenly spaced holes drilled throughout its surface. These holes allow you to insert various hooks, brackets, and shelves to create a customizable storage solution. The standard hole pattern is typically 1/4 inch in diameter with holes spaced 1 inch apart, though variations exist. See standard pegboard specifications

Originally trademarked as "Peg-Board" by the Masonite Corporation in the early 1960s, the term has since become generic for any perforated panel used for organization. Today's pegboards come in several materials, each with distinct characteristics.

Types of Pegboard

1. Hardboard Pegboard

The traditional and most economical option, hardboard pegboard is made from compressed wood fibers. It typically comes in brown or white, though it can be painted to match your space. Hardboard pegboard is lightweight and easy to cut to size, making it adaptable to various spaces.

2. Metal Pegboard

Metal pegboards, usually made from steel or aluminum, offer significantly greater durability than their hardboard counterparts. They resist warping, moisture damage, and won't deteriorate with repeated use. Metal options often feature a powder-coated finish in various colors, with black and white being the most common. For an all-in-one approach, try Wallwerx Starter Kit including a black or white metal pegboard

3. Plastic Pegboard

Plastic pegboards provide a middle ground between hardboard and metal in terms of both price and durability. They're resistant to moisture and won't rust or warp, making them suitable for humid environments like basements or garages in rainy climates. Plastic pegboards come in various colors and are typically lightweight.

Pros of Pegboard

- Affordability: Hardboard pegboard is one of the most budget-friendly organization solutions available, making it accessible to nearly everyone. Even metal and plastic varieties tend to be reasonably priced compared to other systems.

- Customizability: The uniform hole pattern allows for endless rearrangement possibilities. You can easily move hooks and accessories to accommodate new tools or optimize your layout as needs change.

- Quick Installation: Pegboard is relatively simple to install, especially if you use a frame system that creates the necessary standoff from the wall. Most DIY enthusiasts can complete a pegboard installation in an afternoon.

- Visibility: The open design of pegboard makes it easy to see all your tools at a glance, reducing time spent searching for what you need.

- Accessibility: A wide variety of hooks, brackets, and accessories are readily available at most hardware stores, making it easy to expand your system as needed.

Cons of Pegboard

- Weight Limitations: Standard hardboard pegboard isn't ideal for heavy items. The holes can wear out over time, causing hooks to fall out when tools are removed too quickly.

- Durability Concerns: Hardboard versions can warp in humid environments and may deteriorate with repeated use. The holes can become enlarged over time, especially if heavy tools are hung.

- Aesthetic Limitations: Some find the appearance of pegboard, particularly the traditional brown hardboard variety, to be utilitarian and dated.

-

Hook Stability: A common frustration with pegboard is hooks that come loose or fall out when tools are removed. Wallwerx has addressed this design flaw however with secure pegboard hooks that lock in and won't fall out.

- Limited Flexibility for Large Items: While excellent for hand tools, pegboard can struggle to accommodate larger or irregularly shaped items without specialized accessories.

Best Uses for Pegboard

Pegboard excels in certain applications:

- Hand Tool Organization: Hammers, screwdrivers, pliers, and wrenches are perfectly suited to pegboard storage.

- Small Workshop Spaces: The lightweight nature and easy installation make pegboard ideal for small areas.

- Craft Rooms: The versatility of pegboard works well for organizing crafting supplies.

- Budget-Conscious Projects: When cost is a primary concern, pegboard offers the most organization for the least investment.

- Frequently Changing Layouts: If you often rearrange your tools, pegboard's easy reconfigurability is a significant advantage.

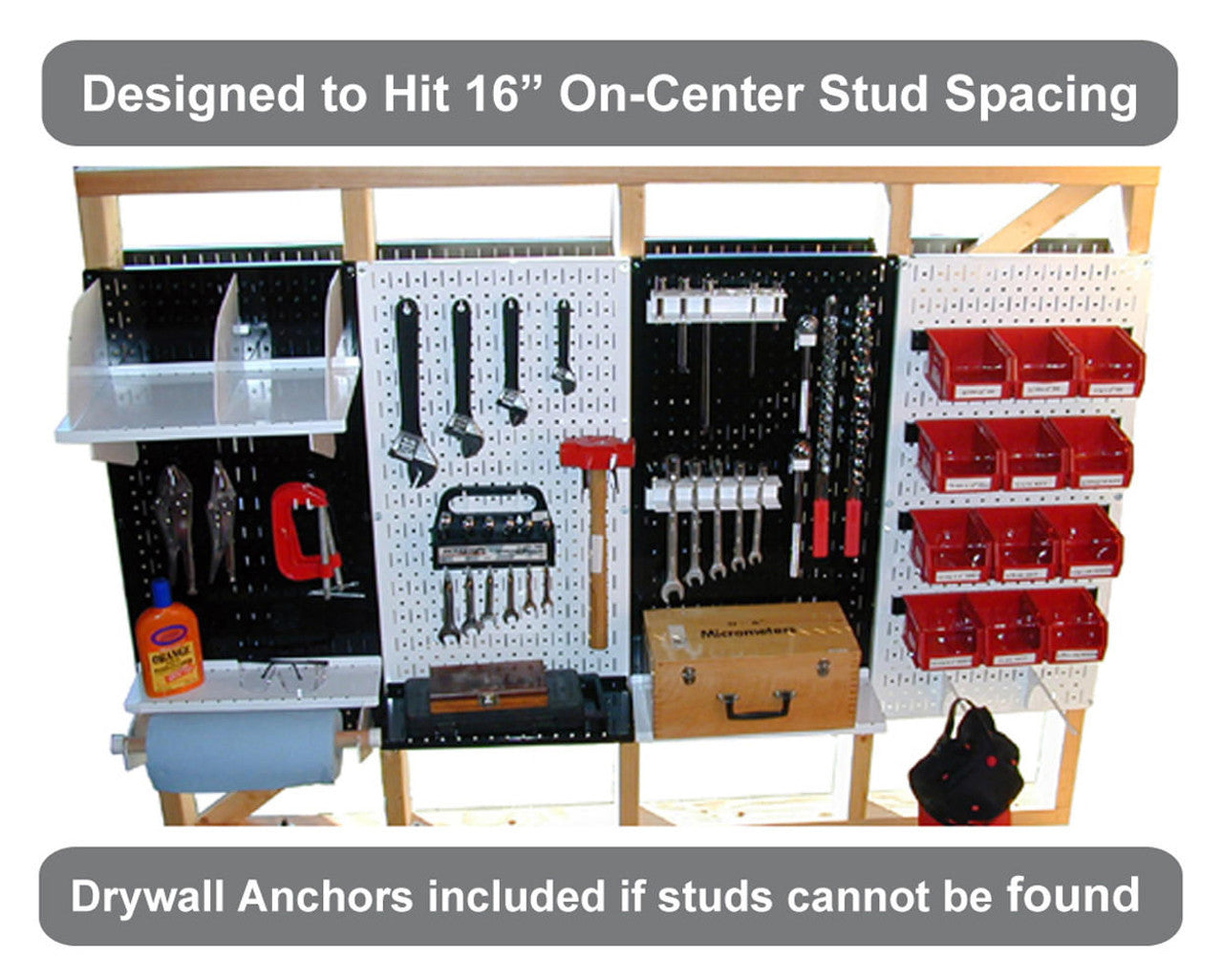

Installation Basics

Installing pegboard requires creating a gap between the board and the wall to allow space for the hooks to be inserted. This is typically accomplished using furring strips or a frame system:

- Locate the wall studs and mark their positions.

- Attach 1x2 furring strips horizontally across the studs, spaced about 16 inches apart.

- Mount the pegboard to the furring strips using screws.

- Add a frame around the edges if desired for a more finished look.

- Install hooks and accessories as needed.

For metal pegboard systems, follow the manufacturer's specific mounting instructions, as these often include specialized hardware or mounting brackets.

Pegboard remains popular for good reason—it's an affordable, accessible solution that works well for many organization needs. However, its limitations with weight capacity and long-term durability have led many to explore alternatives like slatwall and French cleat systems.

Slatwall - Modern Versatility

While pegboard has dominated workshop organization for decades, slatwall systems have emerged as a more modern and versatile alternative. Originally developed for retail displays, slatwall has found its way into homes, garages, and workshops, offering a sleek appearance combined with robust functionality.

What Is Slatwall?

Slatwall (also called slotwall) features horizontal grooves or channels that run across panels. These grooves accept specialized hooks, brackets, shelves, and accessories that slide into place and lock securely. Unlike pegboard's uniform grid of holes, slatwall's horizontal channels create a cleaner, more streamlined appearance while providing continuous mounting options along each groove.

The grooves in slatwall panels are typically T-shaped or L-shaped in cross-section, allowing accessories to hook into the groove and bear significant weight without pulling out. This design creates a more secure connection than traditional pegboard hooks, especially for heavier items.

Types of Slatwall

1. MDF Slatwall

Medium-density fiberboard (MDF) is the most common material for slatwall panels. These engineered wood panels are created by combining wood fibers with resin and wax under heat and pressure. MDF slatwall typically comes with a melamine or laminate finish in various colors and wood-grain patterns. The standard panel size is 4 feet by 8 feet, though custom sizes are available.

2. PVC Slatwall

PVC (polyvinyl chloride) slatwall offers superior moisture resistance compared to MDF versions. This makes it ideal for humid environments like garages in coastal areas or basements prone to dampness. PVC slatwall won't warp, rot, or deteriorate when exposed to moisture. It's available in various colors and can have a glossy or matte finish.

3. Aluminum Slatwall

For maximum durability and a premium appearance, aluminum slatwall represents the high end of the market. These metal panels resist damage, won't deteriorate over time, and can support substantial weight. Aluminum slatwall is typically available in anodized finishes or powder-coated colors.

Pros of Slatwall

- Aesthetics: Slatwall offers a polished, modern look that enhances the appearance of any space. The clean horizontal lines and variety of available finishes make it suitable for both utilitarian workshops and more visible areas like mudrooms or home garages.

- High Weight Capacity: The groove design provides excellent weight-bearing capability, allowing slatwall to handle heavier items that might be problematic for pegboard. This makes it suitable for power tools, large equipment, and even bicycles or ladders.

- Versatility: Slatwall accommodates an extensive range of accessories, from simple hooks to complex shelving systems, baskets, and specialized holders. The continuous horizontal grooves allow for precise positioning without being limited to a grid pattern.

- Durability: Even MDF slatwall tends to be more durable than standard pegboard, while PVC and aluminum versions offer exceptional longevity. The grooves don't wear out or enlarge with repeated use the way pegboard holes can.

- Hidden Hardware: Slatwall creates a cleaner look because the mounting hardware is concealed within the grooves, giving the impression that items are floating on the wall.

Cons of Slatwall

- Installation Complexity: Slatwall installation is more involved than pegboard, often requiring specialized panels and techniques. The panels are heavier and may need stronger wall anchoring, especially if they'll support substantial weight.

- Cost: Slatwall represents a higher initial investment than pegboard. MDF slatwall is moderately priced, while PVC and aluminum versions command premium prices. The specialized accessories for slatwall can also be more expensive than pegboard hooks.

- Accessibility: While becoming more common, slatwall accessories aren't as universally available as pegboard hooks. You may need to order specialized components online rather than finding them at your local hardware store.

- Panel Size Limitations: Standard slatwall panels come in fixed sizes, typically 4'x8', which may require cutting for custom installations. Cutting slatwall, especially the grooved sections, requires more precision than cutting pegboard.

Best Uses for Slatwall

Slatwall excels in several applications:

- Garage Organization: The clean appearance and high weight capacity make slatwall ideal for garage storage, where it can handle everything from garden tools to sporting equipment.

- Retail-Like Displays: For those who want a professional, showroom-quality appearance for their tools or collections.

- Mixed Storage Needs: Spaces that need to accommodate both small hand tools and larger, heavier equipment.

- Humid Environments: PVC slatwall is particularly well-suited to damp locations where hardboard pegboard would deteriorate.

- Visible Areas: When the organization system will be in a visible part of the home where aesthetics matter.

Installation Considerations

Installing slatwall requires attention to detail and proper wall preparation:

- Locate and mark wall studs.

- Ensure the wall surface is flat and clean.

- For MDF slatwall, apply a moisture barrier if installing in potentially damp areas.

- Secure panels directly to wall studs using appropriate screws.

- Use metal inserts in the grooves for maximum strength when needed.

- Consider professional installation for large areas or when maximum weight capacity is required.

Slatwall represents a step up from pegboard in terms of both appearance and functionality. Its modern aesthetic and superior weight capacity make it an attractive option for those willing to invest more in their organization system. However, the higher cost and more complex installation requirements may not be justified for every situation.

French Cleat - Ultimate Customization

For those seeking maximum strength, flexibility, and customization in their organization system, the French cleat offers a compelling solution. This ingenious yet simple approach has been used by woodworkers and craftspeople for generations and has recently gained popularity among DIY enthusiasts looking for a robust alternative to commercial organization systems.

What Is a French Cleat System?

A French cleat system uses pairs of beveled wood strips that interlock to create an extremely strong hanging mechanism. The system consists of two main components:

- Wall Cleats: Beveled strips of wood (typically cut at a 45-degree angle) attached to the wall with the angled cut facing upward and inward.

- Mounting Cleats: Matching beveled strips attached to the back of tool holders, cabinets, or shelves, with the angle cut facing downward and outward.

When the mounting cleat is hung on the wall cleat, the opposing 45-degree angles lock together, creating a secure connection that can support substantial weight. The beauty of this system lies in its simplicity and strength—the heavier the item, the more securely the cleats lock together.

Unlike pegboard or slatwall, which rely on commercially produced accessories, French cleat systems typically involve building custom holders tailored to specific tools and equipment. This makes them particularly popular among woodworkers who enjoy creating custom solutions.

How French Cleats Work

The mechanics of a French cleat system are straightforward:

- A strip of wood (typically 3/4" plywood or solid hardwood) is ripped at a 45-degree angle along its length.

- This creates two matching pieces with complementary bevels.

- One piece is mounted to the wall (flat side against the wall, bevel facing up and in).

- The matching piece is attached to the back of a tool holder or cabinet (flat side against the holder, bevel facing down and out).

- When the holder is hung on the wall strip, the bevels interlock, creating a secure connection.

Multiple wall cleats can be installed horizontally across a wall at various heights, creating a grid system that allows for infinite positioning of tool holders and accessories.

Pros of French Cleats

- Exceptional Strength: French cleats create an incredibly strong connection that can support heavy tools, cabinets, and equipment. The weight-bearing capacity is primarily limited by the strength of the wall mounting and the materials used.

- Ultimate Customization: Perhaps the greatest advantage of French cleats is the ability to create custom holders perfectly sized for specific tools. From oddly shaped hand tools to power tools with unique profiles, custom holders ensure everything has its place.

- Flexibility and Reconfigurability: Tool holders can be easily moved horizontally along a cleat or vertically between cleats, allowing for continuous optimization of your organization system as needs change.

- Clean Aesthetic: French cleat walls have a distinctive, crafted appearance that many woodworkers find appealing. The system creates a clean, intentional look, especially when holders are built with consistent design elements.

- Independence from Commercial Products: While pegboard and slatwall rely on purchased accessories, French cleat systems can be built entirely from scratch, freeing you from the limitations of commercially available components.

- Expandability: The system can easily grow with your tool collection—simply build new holders as needed and hang them on your existing cleats.

Cons of French Cleats

- Time Investment: Creating a French cleat system requires significantly more time than installing pegboard or slatwall. Each tool holder must be custom-built, which demands planning, measuring, cutting, and assembly.

- Woodworking Skills Required: Building effective French cleat holders requires basic woodworking skills and access to tools like a table saw or circular saw for making accurate 45-degree cuts.

- Material Costs: While a French cleat system can be economical if you use scrap wood, building a comprehensive system with quality plywood can become expensive. Two 4'x8' sheets of 3/4" plywood might be needed for a modest wall system plus holders.

- Space Efficiency: French cleat holders typically protrude further from the wall than pegboard hooks, potentially making them less suitable for very narrow spaces.

- Less Standardization: Without standardized components, achieving a consistent look requires careful planning and execution. Holders built at different times may not match in appearance or quality.

Best Uses for French Cleats

French cleat systems excel in several scenarios:

- Woodworking Shops: Where the skills to build custom holders are already present, and tools often have specialized storage needs.

- Heavy Tool Storage: When weight capacity is a primary concern, such as for large power tools or equipment.

- Evolving Collections: For those who frequently acquire new tools and need a system that can easily adapt.

- Custom Workshops: Where standard commercial solutions don't adequately address unique storage requirements.

- DIY Enthusiasts: Who enjoy the process of creating custom solutions and want a project as much as a product.

DIY French Cleat Basics

Creating a basic French cleat system involves these steps:

-

Prepare the Wall Cleats:

- Rip 3/4" plywood or solid wood into strips (typically 3-4" wide).

- Cut a 45-degree bevel along one edge of each strip.

- Mount the strips to the wall, ensuring they're secured to studs, with the bevel facing up and in.

- Space multiple cleats vertically as needed (typically 8-12" apart).

-

Build Tool Holders:

- Design holders specific to each tool or group of similar tools.

- Attach matching cleats to the back of each holder, with the bevel facing down and out.

- Consider adding features like labels, protective linings, or adjustable components.

-

Hang and Arrange:

- Place holders on the wall cleats, ensuring they engage properly.

- Arrange tools logically, keeping frequently used items at easy reach.

- Leave space for future expansion.

French cleat systems represent the most customizable and potentially strongest option among the three organization methods we're discussing. For those willing to invest the time and effort, they offer unmatched flexibility and a satisfying DIY project. However, the significant time investment and required woodworking skills make them less accessible to casual users who need a quick organization solution.

Head-to-Head Comparison

Now that we've explored each system individually, let's compare pegboard, slatwall, and French cleat systems directly across several key factors. This side-by-side analysis will help highlight the strengths and weaknesses of each approach.

Cost Comparison

Initial Investment

| System | Low-End Cost | Mid-Range Cost | High-End Cost |

|---|---|---|---|

| Pegboard | $15-30 for a 4'x8' hardboard sheet | $50-100 for metal pegboard | $100-200 for premium metal systems |

| Slatwall | $50-80 for MDF panels | $100-200 for PVC panels | $200-400 for aluminum panels |

| French Cleat | $30-60 for DIY plywood system | $100-200 for hardwood system | $200-500 for premium materials and finishes |

Accessory Costs

| System | Basic Accessories | Specialized Accessories |

|---|---|---|

| Pegboard | $15-20 for a starter hook set | $40-100 per specialized pegboard kits |

| Slatwall | $30-80 for a starter hook set | $100-200 per specialized kits |

| French Cleat | Cost of materials for DIY holders | Cost of materials plus time investment |

Shop Wallwerx full line of pegboard accessory products

Cost Verdict: Pegboard is clearly the most economical choice for initial setup, especially if you opt for hardboard. Slatwall represents a middle-to-high investment, while French cleats can vary widely in cost depending on materials chosen and whether you value your time investment in building custom holders.

Installation Difficulty Comparison

| System | Skill Level Required | Tools Needed | Typical Installation Time |

|---|---|---|---|

| Pegboard | Beginner | Drill, screwdriver, saw | 2-4 hours |

| Slatwall | Beginner to Intermediate | Drill, screwdriver, saw, level | 4-8 hours |

| French Cleat | Intermediate | Table saw or circular saw, drill, screwdriver, level | 8-16 hours (including basic holders) |

Installation Complexity Factors:

- Pegboard: Requires creating standoff from wall (typically using furring strips), but otherwise straightforward.

- Slatwall: Heavier panels require secure mounting to studs and careful alignment between panels.

- French Cleat: Precise 45-degree cuts needed for cleats, plus time to design and build custom holders.

Installation Verdict: Pegboard is the clear winner for ease of installation, making it accessible to nearly anyone with basic DIY skills. Slatwall installation is moderately more complex, while French cleat systems demand the most time and skill, particularly when including the creation of custom holders.

Weight Capacity Comparison

| System | Light Items (<5 lbs) | Medium Items (5-15 lbs) | Heavy Items (>15 lbs) |

|---|---|---|---|

| Pegboard | Excellent | Fair (hardboard) to Good (metal) | Poor (hardboard) to Fair (metal) |

| Slatwall | Excellent | Excellent | Good to Excellent |

| French Cleat | Excellent | Excellent | Excellent |

Weight Capacity Factors:

- Pegboard: Hardboard pegboard hooks can pull out with heavy items or frequent use. Metal pegboard performs better but still has limitations.

- Slatwall: The groove design provides substantial support, especially with metal inserts in the channels.

- French Cleat: The interlocking 45-degree bevels create exceptional strength, limited primarily by the mounting to the wall and the materials used.

Weight Capacity Verdict: French cleat systems offer the highest weight capacity, making them ideal for heavy tools and equipment. Slatwall performs admirably for most applications, while pegboard (especially hardboard versions) is best limited to lighter items.

Aesthetics Comparison

| System | Traditional Workshop | Modern Garage | Visible Home Spaces |

|---|---|---|---|

| Pegboard | Excellent | Fair | Poor to Fair |

| Slatwall | Fair | Excellent | Good to Excellent |

| French Cleat | Good | Good | Good |

Aesthetic Factors:

- Pegboard: Has a utilitarian, classic workshop look that some find nostalgic and others consider dated.

- Slatwall: Offers a clean, contemporary appearance with various color and finish options.

- French Cleat: Creates a crafted, intentional look that can range from rustic to refined depending on materials and execution.

Aesthetics Verdict: Slatwall typically wins for modern, clean aesthetics, especially in visible spaces. French cleats can achieve a distinctive, crafted look when well-executed. Traditional pegboard has a classic workshop appeal but may look dated in contemporary settings.

Customization Options Comparison

| System | Reconfigurability | Custom Solutions | Commercial Accessories |

|---|---|---|---|

| Pegboard | Excellent | Limited | Excellent |

| Slatwall | Good | Moderate | Good |

| French Cleat | Excellent | Excellent | Limited |

Customization Factors:

- Pegboard: Offers easy reconfiguration with a wide range of commercial hooks and accessories, but limited options for custom solutions.

- Slatwall: Provides good flexibility with commercial accessories and moderate potential for custom solutions.

- French Cleat: Excels in custom solutions tailored to specific tools but has fewer commercial accessories available.

Customization Verdict: French cleat systems offer unmatched potential for custom solutions, while pegboard provides the easiest reconfiguration with readily available commercial accessories. Slatwall strikes a balance between the two approaches.

Durability Comparison

| System | Moisture Resistance | Wear Resistance | Expected Lifespan |

|---|---|---|---|

| Pegboard | Poor (hardboard) to Good (metal/plastic) | Fair (hardboard) to Good (metal) | 5-10 years (hardboard) to 10-20+ years (metal) |

| Slatwall | Fair (MDF) to Excellent (PVC/aluminum) | Good to Excellent | 10-20+ years |

| French Cleat | Varies by material | Excellent | 15-20+ years |

Durability Factors:

- Pegboard: Hardboard versions are susceptible to moisture damage and hole wear. Metal versions resist these issues but may rust in humid environments.

- Slatwall: MDF versions can be damaged by moisture, while PVC and aluminum options offer excellent durability.

- French Cleat: Durability depends on materials used, but the basic mechanism is highly resistant to wear.

Durability Verdict: Metal slatwall and aluminum slatwall systems typically offer the best combination of moisture and wear resistance. French cleat systems made with quality materials are extremely durable. Hardboard pegboard is the least durable option, particularly in humid environments.

Overall Comparison Summary

| Factor | Pegboard | Slatwall | French Cleat |

|---|---|---|---|

| Cost | Low | Medium to High | Variable |

| Installation Ease | High | Medium | Low |

| Weight Capacity | Low to Medium | Medium to High | High |

| Aesthetics | Traditional | Modern | Crafted |

| Customization | Good (commercial) | Good (mixed) | Excellent (custom) |

| Durability | Fair to Good | Good to Excellent | Good to Excellent |

| Best For | Small hand tools, budget projects | Mixed storage, visible spaces | Heavy tools, custom needs |

This head-to-head comparison reveals that no single system is superior in all categories. Each has distinct advantages that make it suitable for different situations and preferences. The best choice depends on your specific priorities, whether they be cost, appearance, weight capacity, or customization potential.

Making Your Decision

With a thorough understanding of pegboard, slatwall, and French cleat systems, you're now equipped to make an informed decision. But how do you translate all this information into the right choice for your specific situation? Let's explore a structured approach to help you determine which system aligns best with your needs.

Decision Flowchart Based on Priorities

Consider which of these factors matters most to you, then follow the recommended path:

If budget is your primary concern:

- For the most economical solution → Hardboard Pegboard

- Willing to spend a bit more for durability → Metal Pegboard

- Want to balance cost with quality → DIY French Cleat (if you have woodworking skills)

If weight capacity is your primary concern:

- Need to hang heavy power tools or equipment → French Cleat

- Need to hang moderately heavy items → Slatwall or Metal Pegboard

- Only hanging lightweight hand tools → Any system works well

If aesthetics is your primary concern:

- Want a modern, clean look → Slatwall (especially PVC or aluminum)

- Prefer a crafted, woodworking aesthetic → French Cleat with consistent holder design

- Appreciate traditional workshop appearance → Pegboard (white or colored options for updated look)

If installation ease is your primary concern:

- Want the simplest installation → Pegboard

- Can handle moderate installation complexity → Slatwall

- Enjoy building and customizing → French Cleat

If durability is your primary concern:

- Need maximum moisture resistance → PVC Slatwall or Aluminum Slatwall

- Need maximum wear resistance → Metal Pegboard or French Cleat

- Working in a climate-controlled space → Any system works, but avoid Hardboard Pegboard

If customization is your primary concern:

- Want to build custom holders for specific tools → French Cleat

- Need readily available commercial accessories → Pegboard

- Want a balance of custom and commercial options → Slatwall

Combination Approaches

Many experienced workshop owners find that combining different organization systems offers the best of all worlds. Consider these hybrid approaches:

Pegboard + French Cleat

Use pegboard for small hand tools and frequently rearranged items, while implementing French cleats for heavier tools and custom storage solutions. This combination offers economy and flexibility for light items with the strength and customization of French cleats where needed.

Slatwall + French Cleat

Install slatwall in visible areas where aesthetics matter, such as near the garage entrance or in multipurpose spaces. Use French cleats in dedicated workshop areas where maximum customization and strength are priorities.

Zoned Approach

Divide your space into zones based on tool types and usage patterns:

- Frequently used hand tools → Pegboard for quick access and visibility

- Power tools and equipment → French cleats for strength and custom holders

- Mixed-use or visible areas → Slatwall for a clean appearance and versatility

Future-Proofing Your Organization System

Whichever system you choose, consider how your needs might evolve over time:

Expandability

- Leave room for expansion on your walls

- Consider how easily the system can grow with your tool collection

- Plan for potential changes in workshop focus or projects

Adaptability

- How easily can the system be reconfigured as needs change?

- Can components be repurposed if you decide to modify your approach?

- Will the system accommodate new types of tools you might acquire?

Investment Protection

- Higher initial investment in quality materials often pays off in longevity

- Consider whether components can be moved if you relocate

- Evaluate the resale value of commercial systems versus DIY solutions

Starting Small and Expanding

If you're uncertain which system is right for you, or if budget constraints prevent a full implementation, consider starting with a small section of wall:

- Test Area: Create a 4'x4' section using your preferred system

- Evaluate: Use this area for a few months to assess how well it meets your needs

- Adjust: Make modifications based on your experience

- Expand: Once satisfied, expand the system to cover more wall space

This approach allows you to refine your organization strategy before committing significant resources to a full installation.

Making the Final Decision

After considering all these factors, you may still find yourself torn between options. In that case, ask yourself these final questions:

- What are my true priorities? Be honest about what matters most—budget, appearance, strength, or customization.

- What are my skill levels and time constraints? Choose a system that aligns with your abilities and available time for installation and maintenance.

- What brings me satisfaction? Some people enjoy building custom solutions, while others prefer the convenience of ready-made systems.

- What's the worst-case scenario? Consider what happens if the system doesn't meet your expectations—how difficult would it be to modify or replace?

Remember that there's no universally "best" system—only the one that works best for your specific situation. By thoughtfully evaluating your needs, priorities, and constraints, you can confidently select an organization system that will serve you well for years to come.

Conclusion

The quest for an organized workshop or garage is a journey that many DIY enthusiasts, homeowners, and professionals undertake with enthusiasm. Pegboard, slatwall, and French cleat systems each offer distinct approaches to this challenge, with their own sets of advantages and limitations.

Recap of the Three Systems

Pegboard stands as the classic, time-tested solution. Its affordability, widespread availability, and simple installation make it an excellent entry point for organization projects. While it may lack the strength and durability of other options, pegboard remains a practical choice for many applications, particularly when budget constraints are a concern or when organizing primarily lightweight hand tools.

Slatwall represents a more modern approach, balancing aesthetics with functionality. Its clean appearance and substantial weight capacity make it ideal for visible spaces and mixed storage needs. Though it requires a higher investment than pegboard, slatwall's durability and versatility often justify the additional cost, especially in spaces where appearance matters or where moderate to heavy items need organization.

French Cleat systems embody the spirit of customization and craftsmanship. For those willing to invest time in creating tailored storage solutions, French cleats offer unmatched strength and flexibility. This approach particularly suits woodworkers and those with specialized tools that benefit from custom holders, though it requires more skill and time to implement effectively.

The Personal Nature of Organization

Perhaps the most important takeaway from this comparison is that workshop organization is inherently personal. The "right" system depends not just on objective factors like cost and weight capacity, but also on subjective elements like your aesthetic preferences, working style, and the satisfaction you derive from different approaches.

Some people find joy in building custom holders for a French cleat system, viewing it as an extension of their craftsmanship. Others prefer the immediate gratification and simplicity of pegboard. Still others value the clean, professional appearance that slatwall brings to their space.

Shop Wallwerx full line of pegboard accessory products

Beyond the System: Organization Principles

Regardless of which system you choose, certain organization principles remain universal:

- Keep frequently used items accessible at eye level and within easy reach.

- Group similar tools together to streamline workflows and projects.

- Create visual order by establishing consistent patterns and arrangements.

- Leave room for growth as your tool collection expands.

- Regularly reassess and optimize your organization as your needs evolve.

Taking the First Step

The most important decision isn't necessarily which system to choose—it's deciding to take action toward better organization. Even an imperfect organization system is vastly superior to tools scattered across workbenches or piled in corners.

Start with a clear assessment of your needs, consider your priorities and constraints, and then move forward with confidence. Whether you choose the economical simplicity of pegboard, the modern versatility of slatwall, or the custom strength of French cleats, you're taking a significant step toward a more efficient, enjoyable, and productive workspace.

Remember that organization systems can evolve over time. Many workshops incorporate multiple approaches, adapting different solutions for different areas based on specific requirements. Don't be afraid to experiment, modify, and refine your approach as you gain experience with your chosen system.

The ultimate measure of success isn't how closely your organization system matches someone else's ideal—it's how effectively it serves your unique needs and enhances your ability to work efficiently and enjoyably in your space.